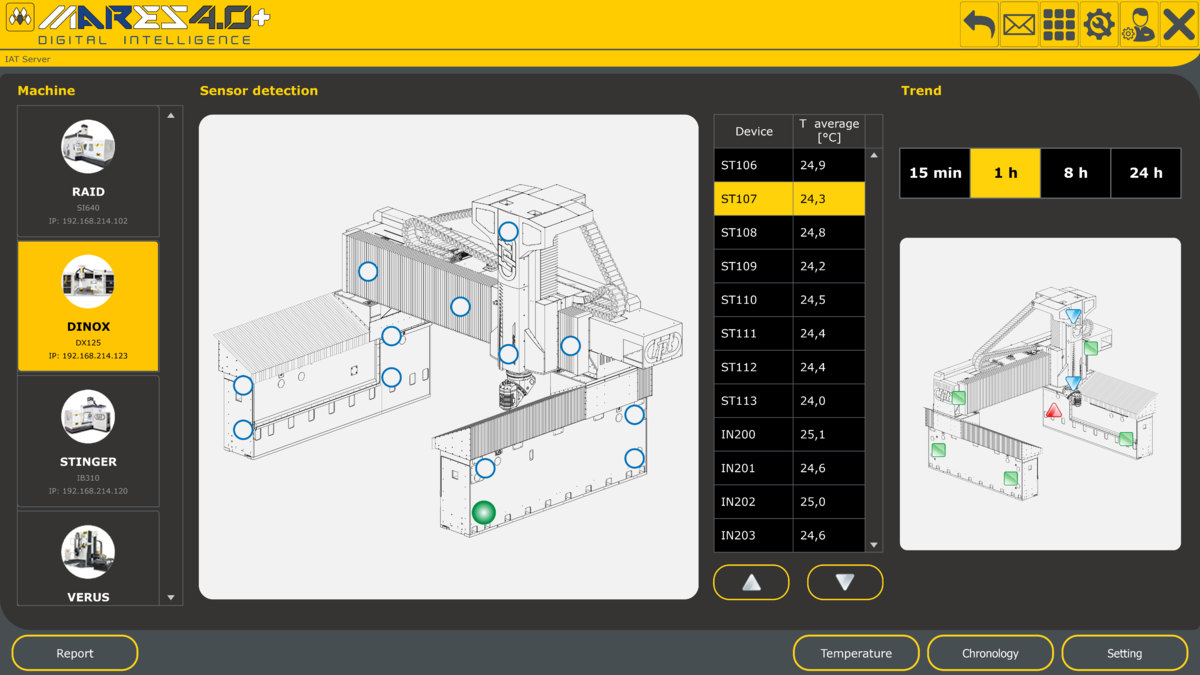

It is the system, studied and defined by FPT in the last years to control and maintain the accuracy of the machine when the environmental temperature conditions change in the place where the machine is installed.

The system is fully integrated in the machine and is made up of these main elements:

- Thermal insulation panels suitably placed in the areas of the machine

most exposed to environmental thermal effects. The panels are

equipped with a special material that acts as a thermal insulator and

are designed to ensure that there are no differences in temperature

on different zones of the same structure during variations in ambient

temperature: in this way the ISOTHERMAL condition of the structures is

achieved and granted.

- Thermal probes for direct and automatic detection of the

temperatures achieved by the different machine structures over time.

The probes are directly connected to the CNC of the machine and the

software developed by FPT acquires the values;

- Thermal probes for the direct and automatic detection of the temperatures achieved by the workpiece in the working area;

- Display panel of machine temperature condition: the panel, placed on the frontal part of the machine near the access doors, allows the user of the machine to see in real time the trend of the measured temperatures;

- Software for acquiring temperature values and for processing an adjustment algorithm.

IAT

Advantages

- Maintenance of the geometric precision of the machine under varying environmental conditions.